Blog 20 October 2020:

I’m Rob Middag and with the help of NIOZ technicians Jan-Dirk de Visser and Bob Koster as well as the officers and crew of Pelagia we are going to test the first prototype of our Ultra Clean Near Bottom Sampler at sea. Today is the first day of the sea trials! For these tests we have installed a camera on the near bottom sampler to see how it lands on the seafloor and we want to determine how long it takes for the initial sediment plume from the landing to dissipate. The first deployment however is done without this camera, as we need to figure out the procedure to deploy and recover and we start simple with the least amount of cables and connections. We do however have a camera in the NIOZ video frame that was hoovering about 20 m above the near bottom sampler. The near bottom sampler remains connected via cables to the ship at all times and it is thus crucial there is enough slack in the cable to prevent movement of the bottom sampler.

Ultra Clean Near Bottom Sampler prototype is deployed for the first time on the Pelagia. The grey tubes are the actual sample collection devices and the orange sphere contains the camera. (In this photo by Bob Koster from left to right, Jan-Dirk de Visser, Stephan Haanstra and Peter van Maurik).

The first deployment was successful! The camera on the video frame showed the rope that connects the near bottom sampler to the video frame was floating in a beautiful arch, indicating the near bottom sampler was standing on the seafloor at 900 m depth undisturbed, unaffected my any surface motions from the ship. And importantly, the samplers collected water very close to the seafloor!

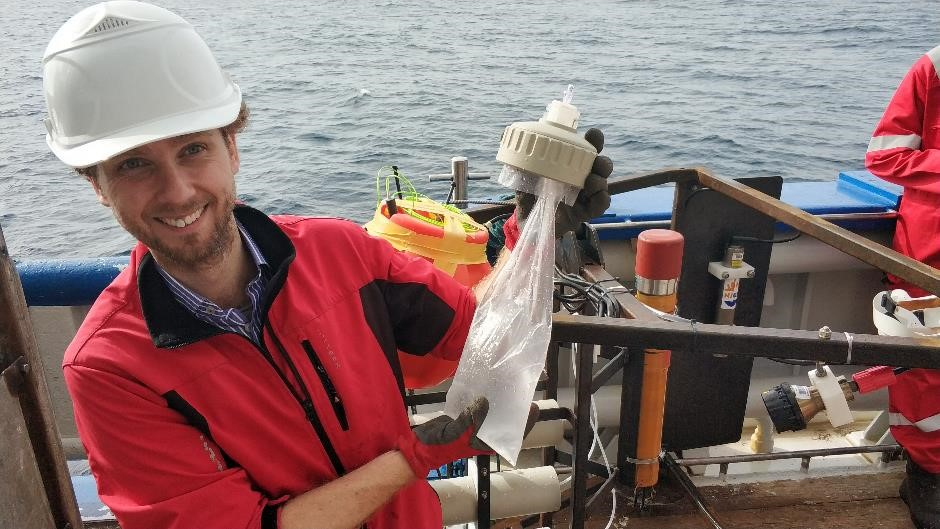

First water collected ~10 cm from the seafloor by our prototype. This one is made of steel and a bit rusty, the next version will be made of titanium and will be usable to sample for trace metals. (In this photo by Bob Koster, Rob Middag).

On the second day we deployed the near bottom sampler under our Titan sampling system for trace metals. This is the device the near bottom sampler is intended to be used with, and for this test we also fitted a camera on Titan. These tests were also successful, we were able to see that the connection between Titan and the near bottom sampler remained slack and we were now able to see the near bottom sampler via live video on the seafloor thanks to Bob’s cameras!

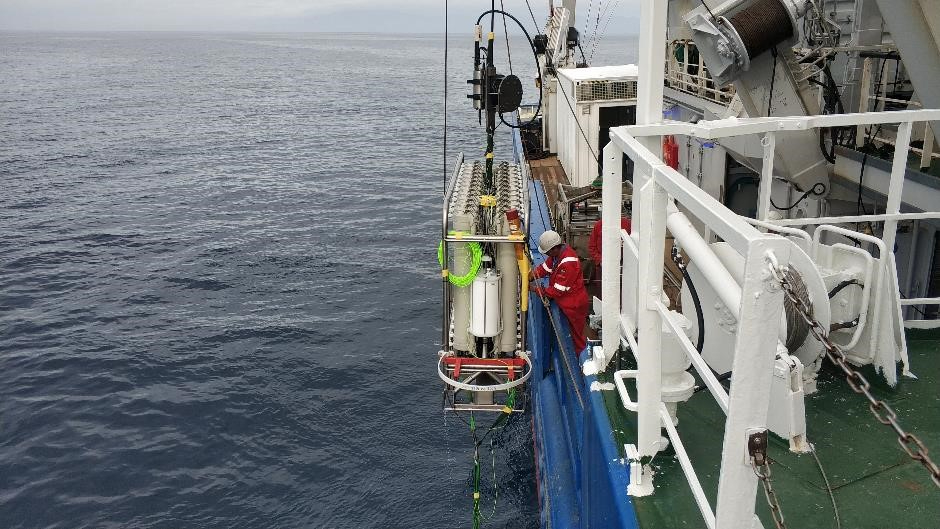

Titan with the prototype Ultra Clean Near Bottom Sampler attached to it. The latter is not visible as it is hanging about 40 m lower under the water surface. (In this photo by Bob Koster, Peter van Maurik).

We increased the number of samplers and did not only have samplers in the near bottom sampler frame, also another 4 attached to the cable above. Above these samplers on the cable, there were 3 floats to make sure this part of the cable was standing upright above the seafloor.

Near bottom sampler with samplers on the line above it as well. (In this photo by Bob Koster from left to right, Cor Stevens (Bosun) and Rob Middag)

The final day we pushed to the limit and we tried to make the near bottom sampler move by letting the ship drift and we challenged the sampler design by blocking the sample inlet. This first test was to determine how much surface movement of the ship is acceptable during deployment, but even after more than 80 m drift of the ship, the near bottom sampler had not moved. This is excellent as this is much more drift than would occur during normal deployments and this result exceeded expectations. The second test was to check if it was possible for water to bypass the sample inlet and filter and seep via other ways. This was indeed the case and thus means there are some minor improvements to be made for version 2.0 of these samplers. This is surely something we can handle and we fully expected the need to adjust the initial design.

Sun setting over the Alboran Sea at the end of the test day (Photo by Bob Koster).

Overall, we were very satisfied with these results and it was amazing to see the process that led us here. It started with the idea to be able to sample near the seafloor. This led to various designs together with the very capably technicians at NIOZ and the first prototype was constructed for testing. With the aid of the skilled sailors and bosun at the Pelagia, a deployment and recovery routine were conceived and the captain and officers did an amazing job in maintaining the ship within several meters of the starting position during deployments. I’m very optimistic about using the next version of the near bottom sampler for obtaining actual samplers next year near Iceland!