Characteristics of RV Adriaen Coenen

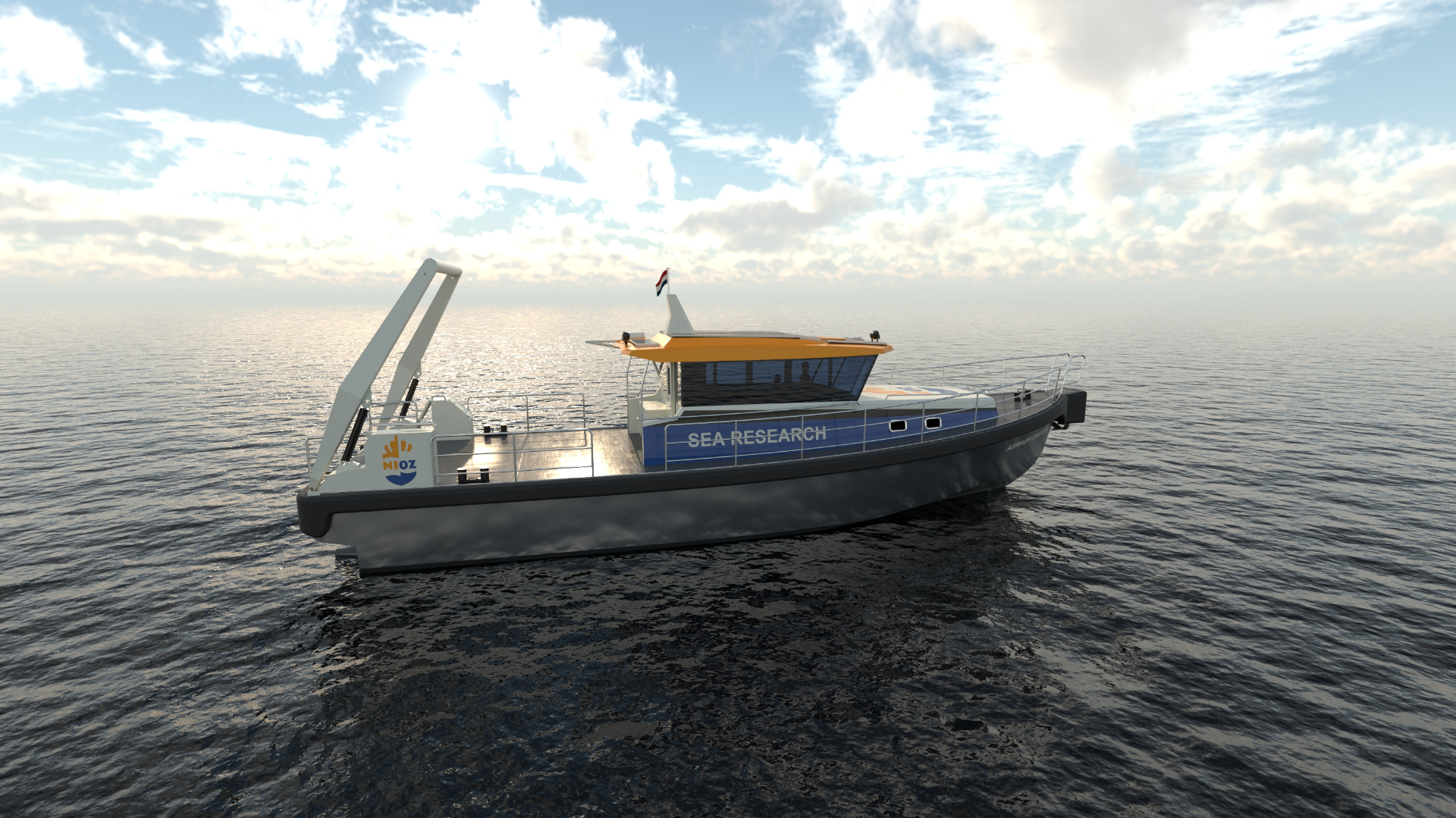

Starting points: sustainability and ideal dimensions

RV Adriaen Coenen is a smart, functional, distinctive and sustainable ship. The ship was designed on the basis of a long wish list of all conceivable Dutch stakeholders. These stakeholders were not only those within the already known academic community, but also from universities of applied sciences (HBO) and applied research organisations (TO2), as well as NGOs. In addition to the NWO and NIOZ ambition for sustainability and green technology, the final ship has bocome a compromise between dimensions and draught to maximise the operational portfolio in tidal areas and shallow waters. “The ship differs from the larger research vessels in that it is equipped for e.g. day trips for the fast and flexible collection of research samples. These can then be further processed at the nearby institute's facilities,” explains Henk van der Veer. As former head of the Department of Coastal Systems at NIOZ, he was closely involved in the design process.

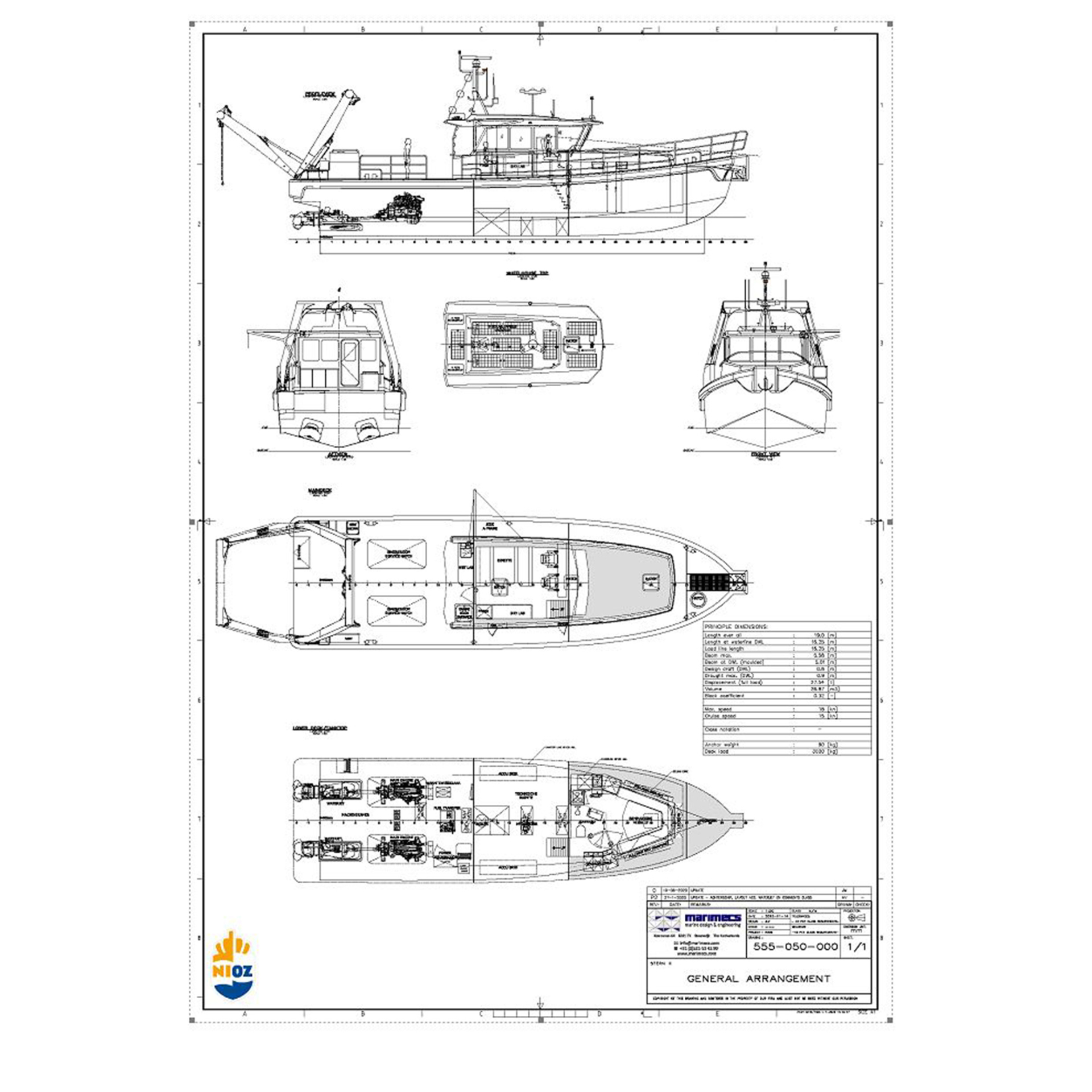

Operational and technical specifications

RV Adriaen Coenen is equipped with facilities for twelve scientists, assistants, students and other passengers, and two crew members. With a maximum draught of 1 metre, the vessel can cross watersheds in the Wadden Sea at high tide and ground during low tide. The new vessel can tow or push small objects such as the 'Wadtower' (a mobile bird observation platform). For research activities, the vessel is equipped with hoisting equipment, a spacious working deck - with room for two rubber dinghies or a 10ft container- arrangements for deployment of ADCP and multi-beam equipment, wet and dry laboratories, ICT infrastructure and communication equipment

As sustainable as possible

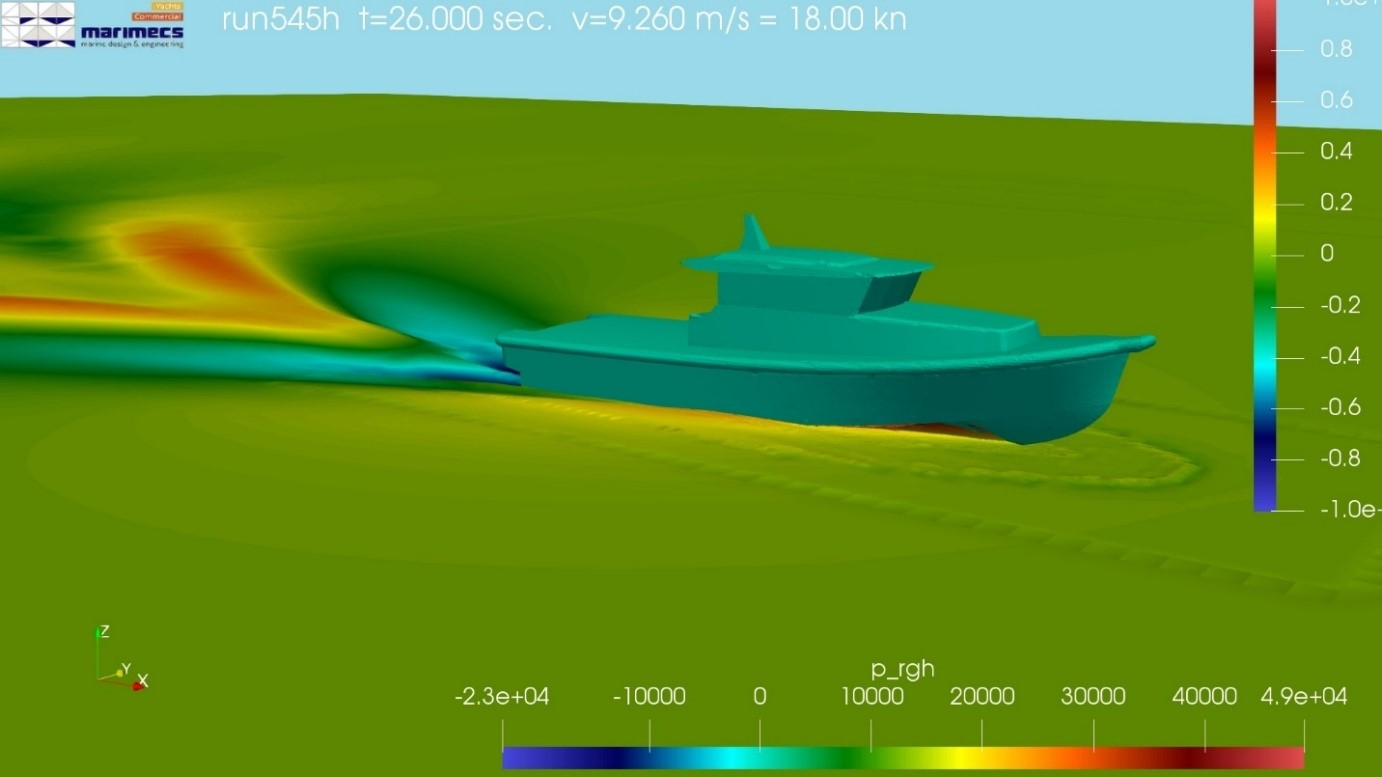

Aarnoud van de Burgt, project manager of the fleet replacement and head of the NMF department, adds: “RV Adriaen Coenen has been built using cutting edge green technology, innovative design and smart construction methods.” The hull was modelled by means of CFD (Computational Fluid Dynamics) simulations and optimised to the best possible hydrodynamic properties. Water jets are used for propulsion, so the ship can easily operate in shallow water and can dry-out.

A diesel substitute, HVO (Hydro-treated Vegetable Oil), is used as an energy source. This ensures a significant reduction in emissions, such as 90% less CO₂. In combination with particulate filters and a catalytic converter on the exhausts, this is at least equivalent to the emission reduction achieved with Methanol, for example.

Furthermore, all installations are designed to minimise energy consumption and, by that means, to reduce waste. For example, the cooling water systems is equipped with a heat recovery system. The LED lighting work swith motion sensors and solar panels. The ship uses batteries when it is dried-out and it a plug-in facility for stays in ports. In addition, maximum (thermal) insulation has been applied.

Specifications

- Length overall 19 m

- Beam 5 m

- Draught 0,8 m

- Material Aluminium

- Speed kts 20 max

- Crew + passengers 2+ 12

- Features A-frame, side frame, ADCP & Multibeam deployment, wet lab, dry lab, towing arrangement

Technical information

- Engines Scania (Stage V)

- Water jets Hamilton

- Cruising: ennbergy from engines (HVO diesel)

- Anchored/grounded: energy from solar panels and battery pack

- Energy back up by small generator